5 Types of Flat Roofs that Business Owners Should Consider

Your business is such an essential part of your life. It helps you achieve most of your goals. And, the last thing you want to happen is to leave your business unprotected. By knowing the different types of flat roofs, you’ll count on a feature that will bring all sorts of benefits to your commercial building!

Restaurants, commercial facilities, hospitals, banks, shopping stores, and many other types of stores get these roof systems installed.

Without further ado, let’s get to our list.

Top Types of Flat Roof Systems:

- TPO Roofing

- Tar and Gravel Roofing

- Modified Bitumen Roofing

- EPDM Rubber Roofing

- Polyvinyl Chloride (PVC) Roofing

5 Popular Types of Flat Roofs: Make a Wise Investment Today

Of course, when you are deciding on the roof type you are going to protect your building with, you must know which are the pros, weaknesses, or any relevant information of each roof type.

With this article, you’ll be ready to make a more informed decision on the different types of flat roofs.

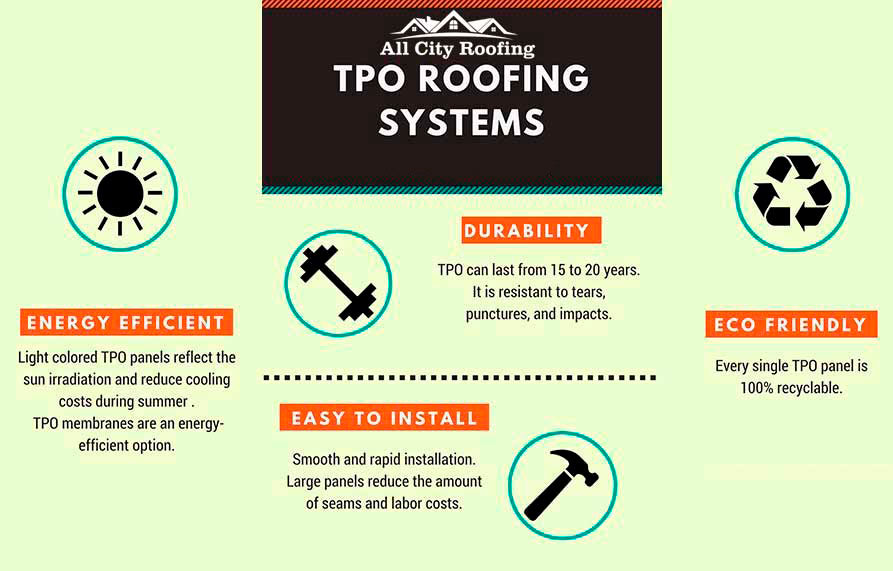

TPO Roofing: Durable, Stylish, Light & Recyclable

Used as a trusted commercial roofing system since 1990, TPO has gained popularity and demand in the flat roofing industry.

But, you might be wondering, WHAT IS TPO? Yes, that’s a hard explanation to give since it has many complicated terms. But let’s make it simple!

TPO stands for thermoplastic polyolefin. This roofing membrane results from a combination of rubber, ethylene, and propylene.

TPO Can Last from 15 to 20 Years

Due to its properties, TPO membranes are highly resistant to tears, impacts, and punctures.

Its fiberglass feature increases the strength and durability of flat roofs. But, besides this, TPO membranes remain flexible, which allows some movement of the building without tearing apart this roofing material.

TPO Sheets Come in Different Sizes!

TPO membranes come in different sizes so that it can be installed in roofs of various dimensions without a problem.

Some of the businesses that tend to install TPO membranes include shopping centers, restaurants, warehouses, and many other flat roof buildings.

Seams between TPO membranes are robust. Thanks to the hot air welding, TPO seams are three times stronger than EPDM rubber seams. So, in this way, you will keep your commercial building protected from water leakage.

Other Benefits Include:

- It has an exceptional puncture & tear resistance

- This material is highly flexible

- It does a great job reflecting heat and sunlight, reducing cooling costs

- Comes in different colors: gray, light-Blue, browns and greens

- It has some degree of resistance to strong chemicals

- TPO is not expensive

- All TPO panels are 100% recyclable

- TPO membranes are resistant to fire and high winds

If you want a durable and appealing roof, TPO roofing is within the top picks of the many types of flat roofs in the market.

Tar and Gravel Roofing

Contractors and builders use gravel on flat roofing for two primary reasons. First, it’s to protect the underlying layer of roofing materials on built-up roofs (BURs). Second, it’s to secure or weigh down the roofing material, as is the case with single-ply flat roofs.

Tar and gravel roofs are one of the most preferred choices among proprietors. It protects your business against external elements such as rain, winds, heat, and snow. Also, it’s also suitable for all flat roof types.

When installing tar and gravel roofing, you need to apply multiple layers of tar-paper, saturated with asphalt. This roofing is made of 3 to 5 laminated layers of asphalt-based sheets, hot tar, and roofing felt. In addition, it contains a top layer of bitumen, an extra top mineral coating, and light-colored gravel to cover the dark layers.

Benefits of Tar and Gravel Roofing:

- Water-Proof Surface

- Low Costs

- Durability

- Easy Installation

- Easy to repair

Modified Bitumen Roofing

This type of roof, just like the name states, is made up of polymer-modified bitumen and reinforced with one or more layers of fabric. You can install it by using conventional methods such as a hot or cold application or self-adhering it.

It is also popular due to its waterproofing feature. Modified bitumen is the top choice if you’re expecting higher than usual foot traffic on your roof.

Many business owners opt for this option due to this roof’s longevity, strength, waterproof features, and energy-efficiency.

This type of roofing comes in two types of membranes:

- Atactic Polypropylene (APP): APP stands for Atactic Polypropylene. This membrane acts like a thermoplastic in the asphalt, reflecting UV rays while protecting you against colder temperatures.

- Styrene Butadiene Styrene (SBS): You install this membrane by using cold adhesive or hot moppings of asphalt. It may also come with adhesive backing.

EPDM Rubber Roofing

EPDM is one of the most durable forms of roofing systems used for flat roof surfaces. It uses a weatherproofing system composed of two main ingredients: ethylene and propylene.

You can find EPDM available in two color choices: black and white. Also, it comes with a broad variety of widths, ranging from 7.5 feet to 50 feet. Lastly, there are two thicknesses for EPDM: 45 and 60 mils.

EPDM can be installed fully adhered, mechanically attached, or ballasted. The installation often includes sealing the seams of the roofing system with liquid adhesives or with a specially formulated tape.

EPDM rubber roofs have been used globally for the last 50 years. The rubber roof membrane offers a wealth of benefits including:

- Heat and cold resistant.

- Environmentally friendly / 100% recyclable.

- Durable, resilient, and long-lasting material.

- Offered in a single, seamless sheet.

- The rubber membrane is waterproof.

- The EPDM roof is lightweight.

- Incredibly low life-cycle maintenance cost.

- Heat-free installation.

Polyvinyl Chloride (PVC) Roofing

Last but not least, polyvinyl chloride (PVC) roofing is another type of flat roof you should know. It is a roof mainly used on commercial or industrial roofs that are flat or low sloped. It’s also the third-most widely produced synthetic plastic polymer.

PVC roofs are fire and chemical resistant. Also, this type of roofing system is very hard to ignite. Lastly, a PVC roof withstands to oxidation reactions. This makes it exceptionally safer than other types of roofs.

The installation method is easy. PVC membranes come in rolls of various sizes and thicknesses. By using the same methods of EPDM, rolls are bound together at the seams through heat welding.

If you want further information, do not hesitate to contact us and, one of our experts will explain our roofing installation methods.

Click on the following link if you want to learn more about the excellent features of TPO roofs.